Does your BMS need to be upgraded?

There are a variety of issues that can trigger the requirement for a Building Management System upgrade. Here are some examples to help you decide.

Failing BMS controllers

This is the least likely reason that you will need to upgrade your BMS.

BMS Controllers are extremely reliable. There have been cases where after 20 years an individual electronic component within the controller has started to randomly fail, but it is more likely that something else will trigger the upgrade long before BMS controllers internal components start to fail.

No longer supported Windows operating system

You would be surprised how often a minor issue unrelated to and out of the BMS suppliers control results in a chain reaction of events that forces an expensive BMS upgrade.

If you have a BMS system that is running, for example, on Windows XP, then you need to be seriously planning for some level of BMS upgrade.

Even if your BMS server application, BMS network controllers and BMS field controllers are still supported, if the computer hardware fails, you can not buy a new computer with a Windows XP operating system.

So, if you go off to Harvey Norman and come back with a new computer running Windows 10, there is a 99% chance that the current version of the BMS application is not supported for Windows 10. In other words, it will not install on the new computer. To resolve this you will need to upgrade your BMS server application to the latest version.

In the perfect world, we would install the new BMS application, update a few databases and be done with it. Unfortunately, it isn't always that easy.

Sometimes, there is a relationship between the BMS server and the BMS network controllers. Upgrading the BMS server application to the latest operating system may not work with the existing BMS network controllers operating system or firmware. You may need to also upgrade the network controllers, and that could kick off a requirement for a complete new database, graphics, alarms and trends etc, which can get expensive.

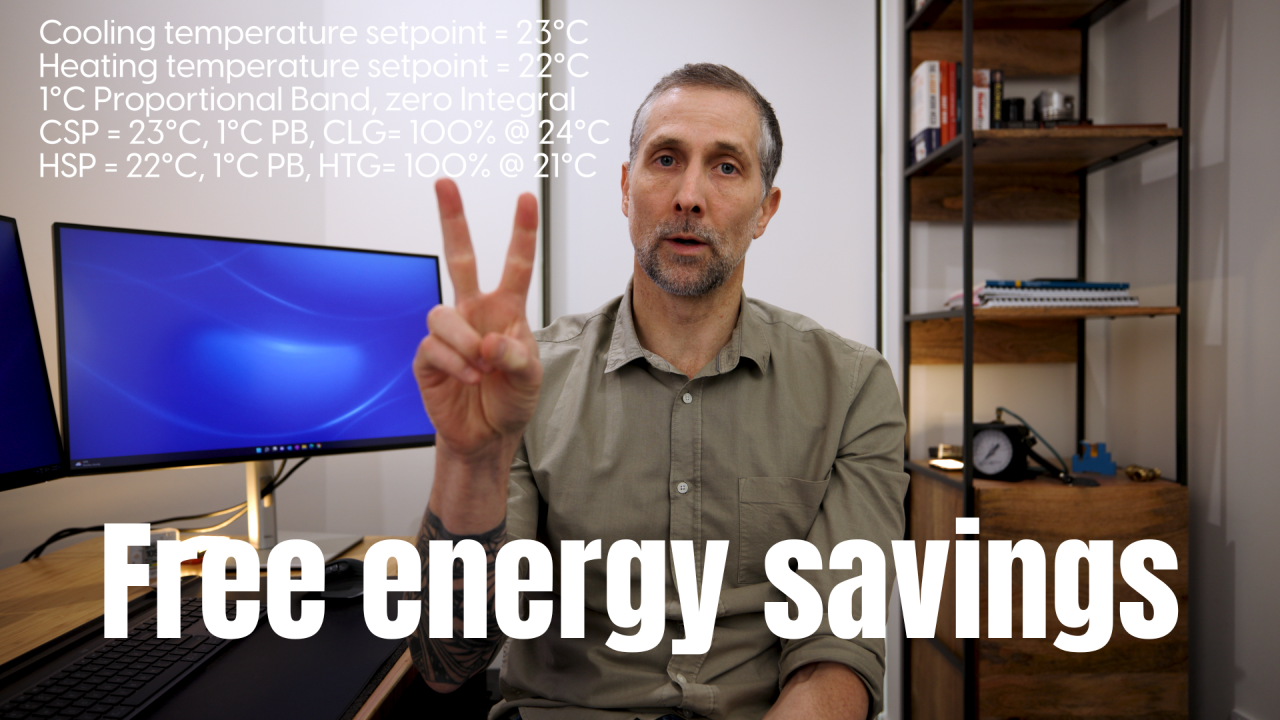

Energy savings

It is often marketed that upgrading your BMS system will result in energy savings. This unfortunately is not completely correct.

Upgrading your BMS can save energy, but not as a result of replacing the field controllers, server, database, graphics, alarms and trends etc. What will save energy is upgrading the control strategies to more efficient modern control strategies and the recommissioning of the inputs and outputs.

In most cases, if you want to save energy, you could retain your existing BMS system and just redesign and download smarter control strategies.

The BMS controllers are no longer supported

If your BMS system is no longer supported, in other words, if a controller fails and a replacement is not available, then you should upgrade or at least have a plan.

You could buy a bunch of spare controllers while they are available to tie you over for as long as possible. However, typically your Windows operating system issue is probably coming into play around the same time and it will force the upgrade.

Or you could put together a 1-3 year plan to upgrade all the non-supported controllers. You do not need to upgrade the whole system at once if you do not have the required budget available.

Keep in mind that we are talking about obsolete controllers here, so, unless you were unlucky enough to get the very last run of a legacy BMS system (this does happen), then your system probably does not communicate using the open BACnet standard, meaning you cannot replace the failed controller with a controller from another company.

As nice as it sounds, to have an open BACnet system where a controller can be replaced with a controller from any BMS supplier, in reality, although it does work, comes with many compromises and challenges.

The BMS is broken

Many BMS systems get upgraded because they appear to be broken; lots of communication issues, online/offline controller alarms, 100's of alarms each day, slow graphic updates, poor energy efficiency, etc, the list goes on.

In almost all cases, the perceived broken BMS is the result of one or more of the following (often all), and not the physical controllers themselves:

Poorly designed network infrastructure and network device loading per sub-network.

Poor design: functional description, points list, valve and damper schedules etc.

Poor network installation quality

Poor software programming

Minimal understanding of mechanical systems

Lack of commissioning

Poor maintenance, etc

Usually, upgrading the BMS will flush out some of these issues, but you probably don't need to completely replace the whole system.

Some BMS companies use offshore software engineering (e.g. India). Often the engineer writing the software code is not a controls specialist in the HVAC (heating, ventilation and Air Conditioning) industry, but a computer programmer that has been taught how to program using the BMS companies programming tool. Poorly designed software control strategies can cause a massive issue in how reliably or efficiently your building operates.

Also, in many countries, the BMS equipment (control panels, cables, sensors and actuators) is installed by electricians, not BMS technicians. This used to be okay because the BMS commissioning technician would check that the actuator was properly coupled to the valve or damper, and that the sensors were installed in the correct locations etc. However, now that commissioning time frames are compressing to the point that in some cases commissioning isn't being done at all, is resulting in poorly installed and commissioned inputs and outputs. Note: checking that a valve or damper opens and closes, from a laptop 5 meters away is not commissioning.

It is not that uncommon for building owners to be handed a brand new BMS system that is 'broken'.

Relationship breakdown between the BMS contractor and the building owner or manager

Occasionally, BMS upgrades happen because the relationship between the owner and the BMS contractor has broken down to the point that they will spend any amount of money to get a different system. Usually, to do with high costs or high perceived costs for project work and maintenance or poor performance.

I have assisted in resolving this breakdown on a few occasions, and here is my view on this from past experience.

If you are getting nowhere with the BMS account manager, get the branch manager in the room. In my experience, this has improved the relationship every time.

You get what you pay for. Unfortunately, sometimes the issue originates from the maintenance contract value being reduced, leaving the BMS contractor with just enough time to spot check a couple of things and react to a couple of temperature complaints per quarter, with no maintenance actually being performed.

BMS companies are all quite similar, so are their products; the difference is the people assigned to your building or project. Never assume that you will be better off with another system or company.

Featured - Latest published online course

BMS for mechanical consultants course

This course was developed by a BMS consultant for mechanical consultants involved in Building Management System projects. Learn how to reduce risk to your company, your client, and the BMS contractor.

Self-paced online course.

12 hours of video lessons.

Training manual (+90 pages).

BMS design examples.

A sample of Lifecycle Controls BMS specification clauses are provided to assist with learning. You can use these in your own specification.

Online shop

Free control strategy mini courses

Create a free account in our Learning Management System and complete the free chilled water control system mini-course. A certificate is provided at the end of the course. A copy of the control strategy is provided as a Microsoft Word document for you to modify in your own BMS designs.

Please join our newsletter

To be notified when new courses, design templates, and digital products are published.

For updates to coaching availability.

For updates to business-to-business consulting services.

New Youtube video releases and occasional updates on what I am up to.

I will not fill up your inbox with crap.

Bryce Anderson

I am an independent Building Management System consultant based in Australia. I started in the BMS industry in 1998 and initially worked for BMS companies for the first 15 years of my career (2 years in South Africa, 9 years in London, and 4 years in Melbourne). In 2014 I transitioned into BMS consulting, saw a massive gap in the lack of specialist BMS consulting, and started Lifecycle Controls in 2017.

My focus is currently on BMS technical training, coaching, and B2B consulting for BMS companies and mechanical consultancies. Because, fixing one project at a time was making no difference. Training thousands of engineers will :-)