How much of a BMS upgrade directly results in energy savings?

Energy efficiency and hardware end of life are two common reasons for BMS upgrades. If the BMS controllers are failing or are no longer supported, then a complete upgrade may be required. However, in many cases a complete upgrade is not required as part of an energy efficiency upgrade.

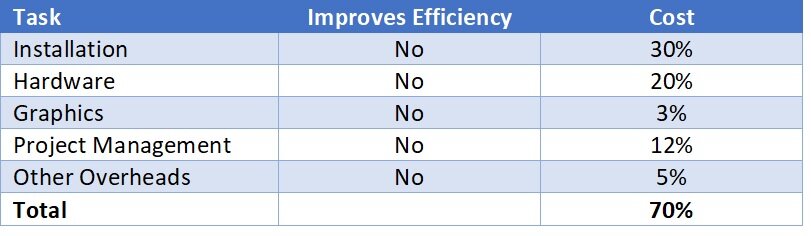

The table below lists the BMS upgrade tasks as a cost percentage* that do not directly result in energy savings, in other words, the money that you spend doesn’t directly translate into an increase in NABERS rating or reduction in utility bills.

For example, the electrician physically replacing the current controller with a new controller does not save energy. Rebuilding the graphics, database, alarms, trends and user accounts does not save energy. The cost of the physical BMS controllers does not save energy. Project management costs do not save energy. Sales overhead and margin do not save energy.

The table below lists the BMS upgrade tasks as a cost percentage* that result in energy savings. For example, designing new energy efficient control strategies does save energy.

Approximately 70% of the cost to upgrade the entire BMS does not directly result in energy savings, only 30% of the cost results in energy savings. Therefore, if your primary driver is to save energy, improve your NABERS rating and attract higher profile tenants, then only upgrade the control strategies.

The commissioning cost in the table above is to commission each input and output point once the controller is replaced. Technically, we don’t need to recommission the points if we don’t replace the controller, however, in this comparison I have kept the 20% cost to commission the new software control strategies.

If demanding energy improvement targets have been set over the next 12 months you could consider delaying BMS periodic preventative maintenance for 12 months and redirecting some of the maintenance budget towards control strategy optimisation.

* The cost percentages above were averaged from four office tower BMS upgrades from the same tier one BMS manufacturer, in the range of $500,000 to $700,000. The purpose of this comparison is to give you a feel for where the money goes. Depending on the building type, building grade, geographical region, type of BMS company and scope will vary the percentage of each break up.

Featured - Latest published online course

BMS for mechanical consultants course

This course was developed by a BMS consultant for mechanical consultants involved in Building Management System projects. Learn how to reduce risk to your company, your client, and the BMS contractor.

Self-paced online course.

12 hours of video lessons.

Training manual (+90 pages).

BMS design examples.

A sample of Lifecycle Controls BMS specification clauses are provided to assist with learning. You can use these in your own specification.

Online shop

Free control strategy mini courses

Create a free account in our Learning Management System and complete the free chilled water control system mini-course. A certificate is provided at the end of the course. A copy of the control strategy is provided as a Microsoft Word document for you to modify in your own BMS designs.

Please join our newsletter

To be notified when new courses, design templates, and digital products are published.

For updates to coaching availability.

For updates to business-to-business consulting services.

New Youtube video releases and occasional updates on what I am up to.

I will not fill up your inbox with crap.

Bryce Anderson

I am an independent Building Management System consultant based in Australia. I started in the BMS industry in 1998 and initially worked for BMS companies for the first 15 years of my career (2 years in South Africa, 9 years in London, and 4 years in Melbourne). In 2014 I transitioned into BMS consulting, saw a massive gap in the lack of specialist BMS consulting, and started Lifecycle Controls in 2017.

My focus is currently on BMS technical training, coaching, and B2B consulting for BMS companies and mechanical consultancies. Because, fixing one project at a time was making no difference. Training thousands of engineers will :-)