How can we install and commission the BMS faster?

The days of practical completion dates being pushed back to allow for Building Management Systems to be properly commissioned are over. In this article, we will discuss an alternative delivery method that should allow installation to start earlier and create some breathing room between commissioning and practical completion.

In my opinion, one of the bottlenecks delaying the start of BMS installation is the MSSB (Mechanical Services Switchboard), which is installed in a central location in each plant room, requiring all BMS instrumentation (sensors and valves, etc), to be wired back to one location in the plant room.

Well, then lets get rid of it.

Current BMS installation and commissioning method

The following is generally the sequence of who has installation priority in the plant room. And often, if it’s not your turn or there isn’t anything to hang your containment off, then you need to wait.

Mechanical contractors have first priority to install duct and pipe through the plant room.

At the same time, the main electrical contractor installs the main power feed to the location of where the MSSB will be installed, and whatever other main electrical cables need to run through the plant room to other areas.

The mechanical electrician then has priority to install the power feeds from the MSSB to the AHU VSD's.

During the same time frame, the BMS installer is either waiting or is starting minor rough-in on the AHU's, but is mostly unproductive as there is either no route back to the MSSB yet or other trades have priority.

The MSSB is then delivered and the mechanical electrician has priority to complete cable terminations. The rush is then on to get the MSSB powered up for air and water balancing to start, which should have started 2-weeks ago.

BMS installation time just got compressed from 2 weeks to 2 days, as we need to power up the MSSB urgently. Air and water balancing is on the critical path, no one cares about BMS at this stage.

Once air and water balancing are complete, mechanical witnessing starts. We used to have a few weeks to commission the BMS after air and water balance witnessing, but, because of compressed commissioning timeframes, practical completion is now often straight after air and water balance witnessing.

BMS commissioning just got compressed from 2 weeks to 2 days.

Last year I witnessed a BMS system at the exact same time that air balancing was being witnessed. All the VAV’s overridden to Vmax, all the AHU’s at set at design volume, all the economy dampers set to design outside air. Commissioning is not just getting compressed, it’s not happening at all.

So I thought, okay, I’ll just start with water side BMS witnessing. Well, the project ran so late that once the MSSB’s were powered up, all the valves were immediately overridden open and water balancing started, before they were commissioned. So, now, a few days before practical completion, the chilled water and hot was systems are in auto, but the valves were never commissioned. And, I am trying to do witnessing.

Distributed control panels

If we take a plant room with four AHU's for example, the AHU's are usually delivered early, as they are long lead items and need to be in position while there is still a clear route into the plant room. If we move each BMS controller from the large centrally located control panel into smaller control panels on each AHU, then most of the inputs and outputs can be wired locally at the AHU. 3-Months before power on dates, we can wire at each AHU, the supply air temperature, humidity and pressure sensors. The economy damper actuators, dirty filter monitoring, and heating and cooling valves (ask mechanical to install the valves early at the AHU). If you coordinate for the VSD’s to be installed early on the AHU, then you can wire the BMS start-stop, speed, run and fault points and the high-level interface.

Lets take a step back. Why do we have MSSB's?

Before VSD's we needed a panel to house the star/delta contactors, overloads there timeclocks. We mostly now have VSD's, which need to be permanently powered, so there is no longer a need for contactors in the MSSB.

We needed Run and fault lamps, because before BMS systems, that was the only way to check that the motors were running and that the overload on the contactors hadn't tripped. Facility managers no longer walk through plant rooms at 6am to make sure everything is running; general status checks are done at the BMS. If you have a major failure of the BMS you can interrogate the VSD keypads for Run and Fault status.

We needed Hand/Off/Auto switches because there was no other way to override the contactors. Overrides can now be made at the BMS or at the VSD keypads.

Why do we have Hand/Off/Auto switches and Run/Fault lamps on MSSB’s? Because we needed them 20-years ago. We don’t need them anymore. If we remove the Hand/Off/Auto switches and the Run/Fault lamps, and we don’t have contactors, we pretty much just have a Distribution Board.

Distributed power (no MSSB)

There are a couple of ways to move forward without an MSSB. Install a small distribution board next to each distributed control panel on each AHU to house the following circuit breakers:

3-phase supply to the supply fan VSD

3-phase supply to the return fan VSD

1-phase supply to the AHU lighting

1-phase supply to the BMS control panel

Other than wiring all available instrumentation on the AHU 3-months early, we can now also pre-wire power to the VSD's with isolators etc. As there is no longer an MSSB, the start-stop signal now comes directly from the BMS controller, so we can pre-wire those.

The original intent when I started looking into this in 2009 was to have AHU's fully wired with power and controls at the AHU factories. This didn't work within the tight time constraints of an AHU manufacturing line, but it was worth a try. I found that it was just as effective to install the power and controls directly onto the AHU’s after they were delivered.

Even though we have distributed the power out to the AHU's, we still need a main distribution board in the plant room to supply power to each AHU's mini distribution board, or it can come from the main electrical board. At least now we only have one 3-phase power supply to each AHU rather than three or four separate power supplies. And, those power cables are installed by contractors who have priority in the plantroom before the BMS installer.

Fire and smoke control introduces a challenge as the MSSB traditionally houses these interlocks. Rather than running the fire-rated communications cable to MSSB and installing the fire interfaces at the MSSB, simply run the communications cable round the plant room past each AHU and install the fire interfaces next to the VSD's. Now, this is a little complicated, but it can be done, and it’s definitely worth it.

The purpose of removing the MSSB should not be seen as a potential cost-saving; distributing power and controls will likely increase the cost of the installation. The purpose is to de-risk the delivery of the BMS on practical completion and not to save money. Unfortunately, we are still restricted by what can be achieved within the limitations of 'lowest price wins'. I believe that in the future the focus will shift from who can build the cheapest to who can build the fastest. Well, it actually has, just not in Australia.

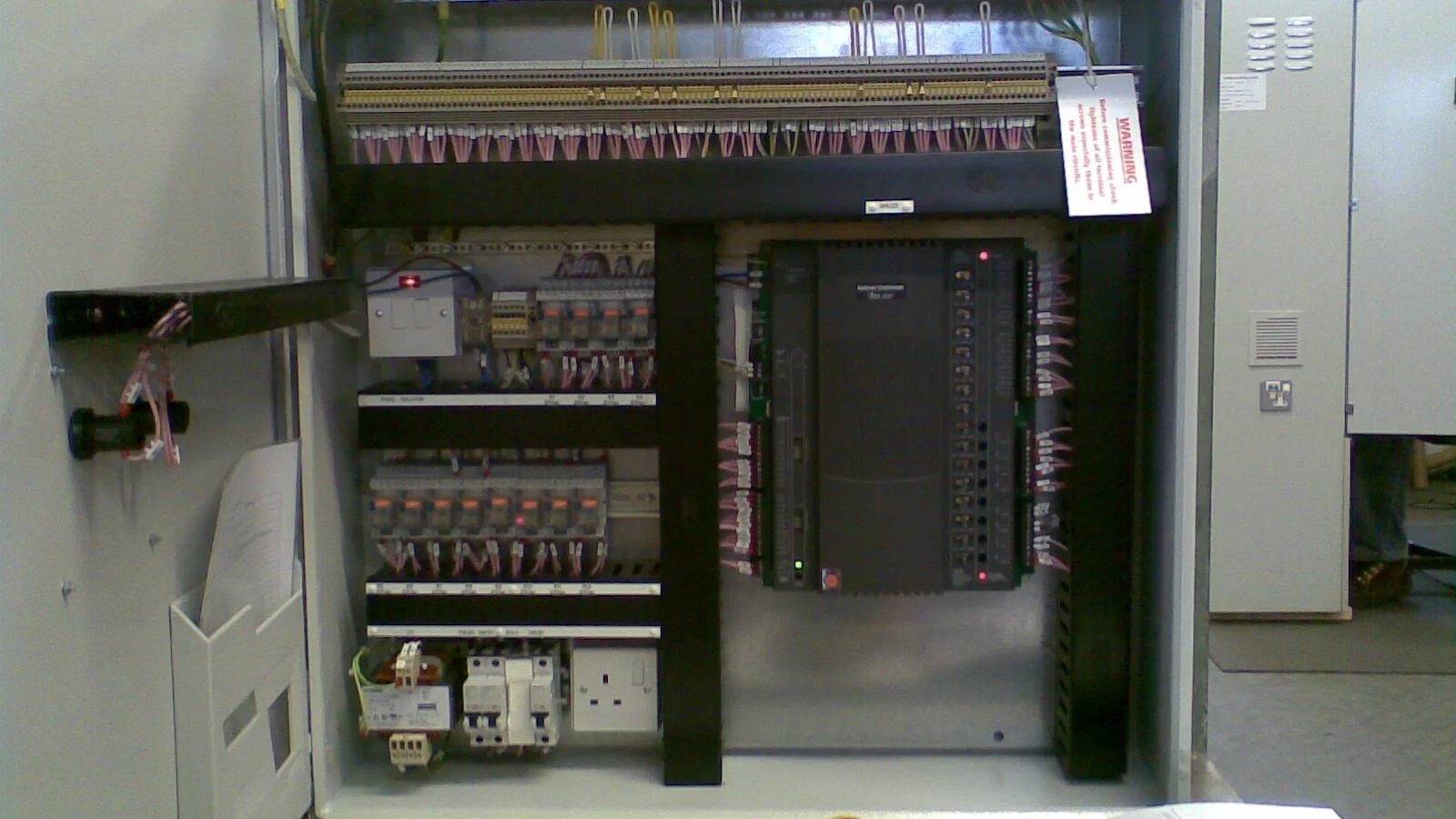

In 2008-2010 I was employed by Lang O'Rourke in London designing BMS systems for offsite manufacture. Here we have a control panel installed on each AHU. This AHU was for an operating theatre, so we had duty/standby supply and return fans. Notice how the AHU is still sitting on wooden blocks. The BMS installation started months before scheduled install start dates.

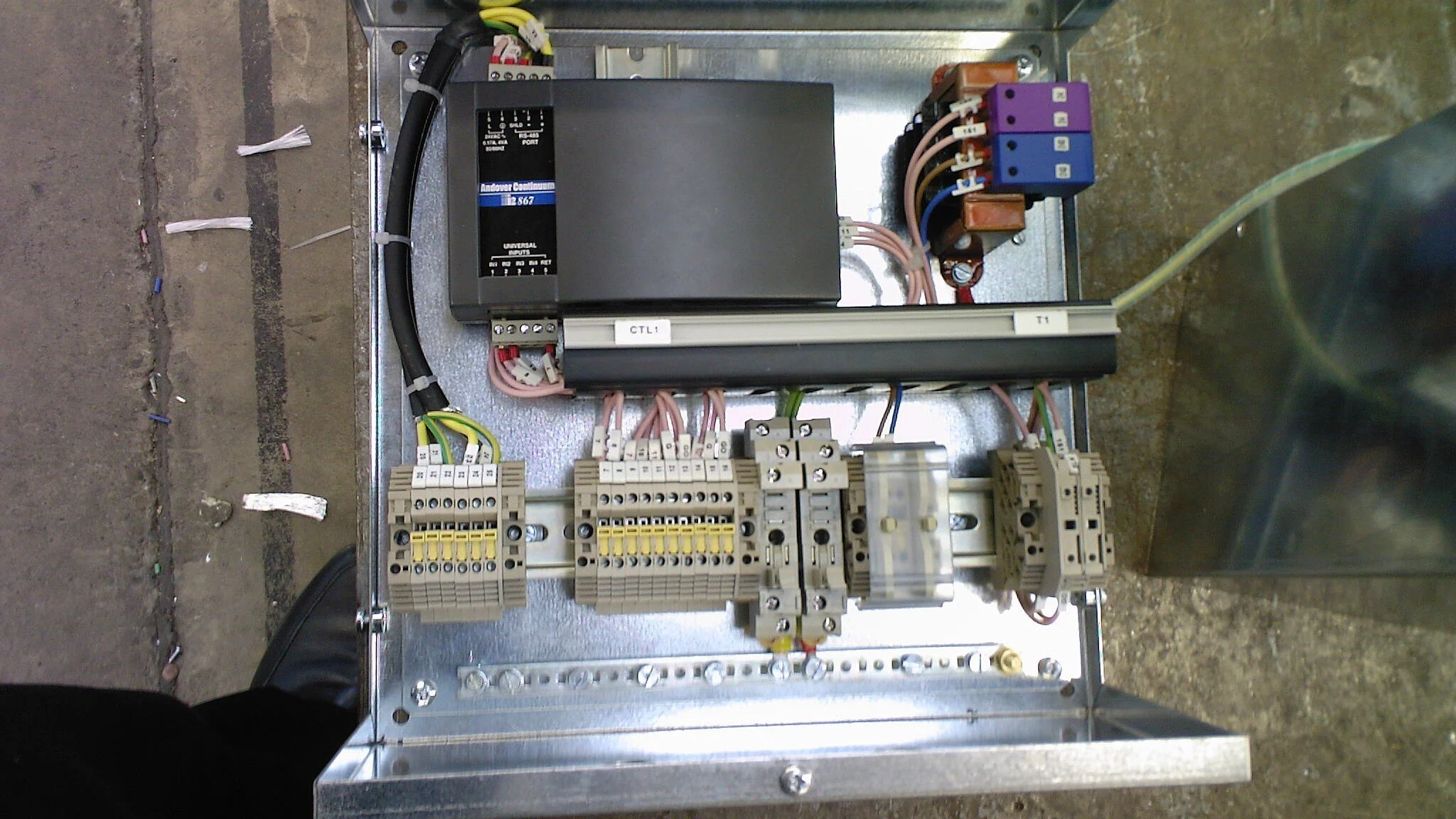

In the picture below, I was testing the first AHU control panel at the panel manufacturer to make sure it was 100% correct before approving mass production (52 AHU's I think). Note the knife-edge terminals at the top. We used these because any sensors not capable of being fitted off early would have their 24Vac power and signal isolated. The relays in this panel would have traditionally been in the MSSB but have now be moved into the control panel. I designed this control panel to suit all AHU types, if an AHU didn’t have run around coils, then those terminals just didn’t get wired. If you needed an AHU control panel, you just grabbed one from the store, any one,

In this photo, the first of 4 offsite manufactured skids making up a complete chilled water plant room (excluding the chillers) is being positioned. Water balancing started 3-days after the skids were delivered.

In this photo, the skid is still on the back of the truck. You can see the control panel, power board and 2 smaller distribution boards on the left. The remaining 3 skids housed the primary and secondary pumps, heat exchanges, pressurisation units and VSD's.

Here I am testing the first FCU, chilled beam, PAC unit controller at the panel manufacturer, before approving mass production. These control panels were issued to the FCU supplier for installation at their factories. Note the knife-edge terminals, in this case, not to assist in temporary power and early commissioning, but to assist the FCU supplier in easily pre-wiring fan and valve actuators.

Featured - Latest published online course

BMS for mechanical consultants course

This course was developed by a BMS consultant for mechanical consultants involved in Building Management System projects. Learn how to reduce risk to your company, your client, and the BMS contractor.

Self-paced online course.

12 hours of video lessons.

Training manual (+90 pages).

BMS design examples.

A sample of Lifecycle Controls BMS specification clauses are provided to assist with learning. You can use these in your own specification.

Online shop

Free control strategy mini courses

Create a free account in our Learning Management System and complete the free chilled water control system mini-course. A certificate is provided at the end of the course. A copy of the control strategy is provided as a Microsoft Word document for you to modify in your own BMS designs.

Please join our newsletter

To be notified when new courses, design templates, and digital products are published.

For updates to coaching availability.

For updates to business-to-business consulting services.

New Youtube video releases and occasional updates on what I am up to.

I will not fill up your inbox with crap.

Bryce Anderson

I am an independent Building Management System consultant based in Australia. I started in the BMS industry in 1998 and initially worked for BMS companies for the first 15 years of my career (2 years in South Africa, 9 years in London, and 4 years in Melbourne). In 2014 I transitioned into BMS consulting, saw a massive gap in the lack of specialist BMS consulting, and started Lifecycle Controls in 2017.

My focus is currently on BMS technical training, coaching, and B2B consulting for BMS companies and mechanical consultancies. Because, fixing one project at a time was making no difference. Training thousands of engineers will :-)